FARM GROWN SOLUTIONS

Twine Spool – shape

Twine Spool – care

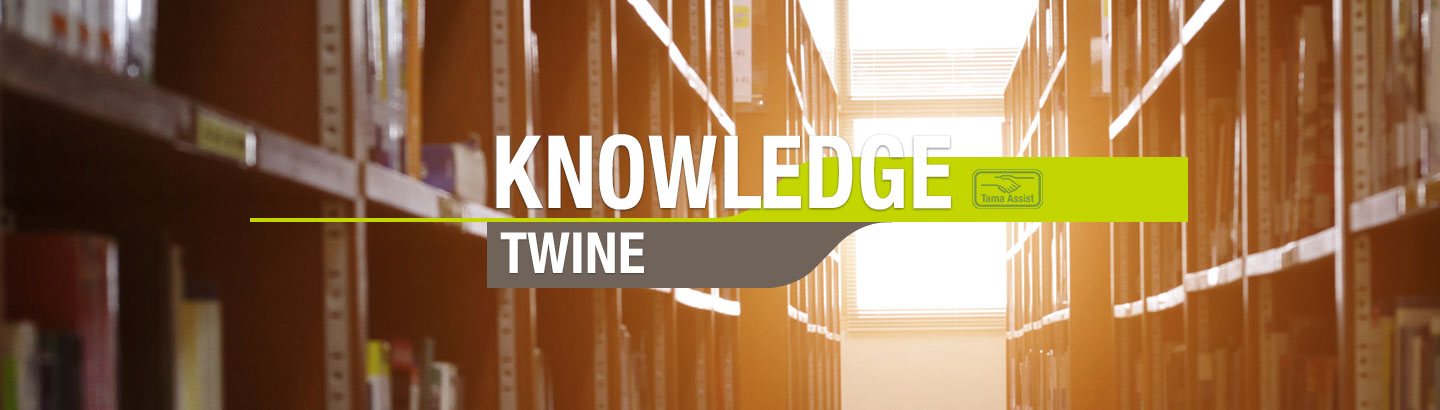

Twine Spool – size

Spools must be correct size to easily fit in the storage box on the baler, so as not to be damaged when loading. Ensure that spool fits easily into the box.

If the spool is too big, and needs to be forced into the box and become crushed, it could disturb the accurate winding inside the spool and create problems when in use (as shown above).

Ensure the spool is not too tall, and can fit easily below the twine guides in the top of the twine box on the baler. If there is insufficient space above the spool, the twine may not be able to pull freely from the spool.

Twine Spool – correct alignment

Twine Spool – joining

On Double-knotter balers, it is important NOT to join different types/thickness of twine on same knotter

Ensure that the Upper and Lower twines are of the same type and diameter, to avoid any risk of knotting problems caused by twine slipping and knots opening.

BALER CHECK

Twine box

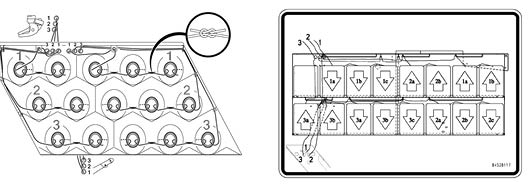

Ensure the spools are correctly connected and routed through the baler to the knotter.

Check that the twine spools are connected in the correct order, as per the baler manufacturer’s recommendation.

Twine tension settings

In order that a correct and secure knot is made, it is essential that twine tension is correct and all tension devices are adjusted correctly to achieve this.

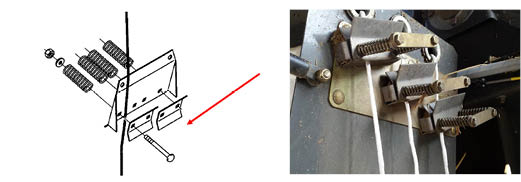

Tension plates

Ensure the twine tension plates are adjusted correctly, as per operator manual

Adjust the twine tensioners at the twine box with slight tension to prevent twine free falling.

Ensure twine tension plates are kept clean and free from crop debris, which if allowed to build up between the plates,

can reduce the twine tension.

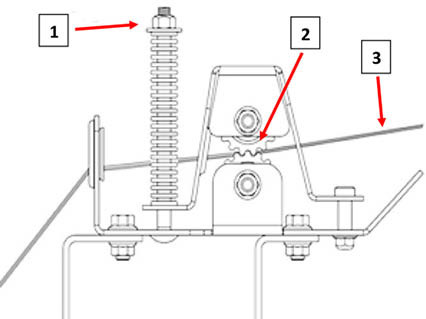

Tension rollers

Pull the twine (3) from inside the chamber, with a spring-balance

Adjust the springs (1) on the tension rollers (2) to give a pull-tension of 6 – 8kg

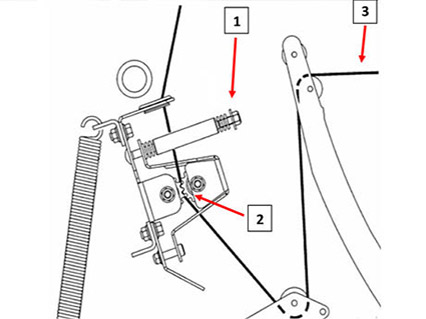

Twine guides

Check carefully, and regularly, the twine guide rings below the baler, between the twine boxes and the needles.

Worn or damaged guides can damage the twine, breaking fibres and reducing the twine strength.

Knotters

Needles

TWINE GENERAL KNOWLEDGE

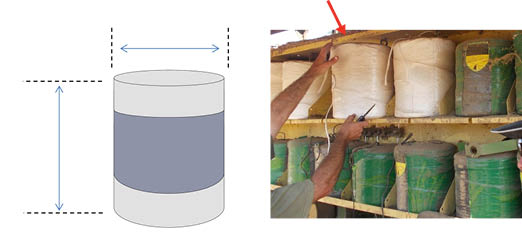

In all spools of Tama Twine, 15m of twine is removed to minimise the effect of deformed twine at the start of each new spool use.

When under the correct tension inside the baler, any wrinkled twine will tighten fully to operate normally in the knotter.

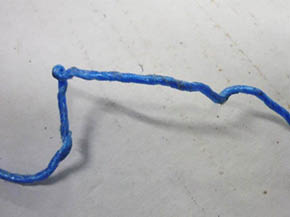

Knots

Depending on the OEM make of baler, there are two types of knots made by large-square balers. The knots are quite different and have an impact on the overall ‘strength’ of the twine after the bale is made.

Cormick knot (or ‘Loop’ knot)

All Claas Quadrant and Welger large square balers have knotters which make a Cormiock knot.

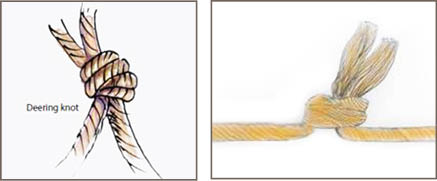

Deering knot

All other makes of baler (Single or Double-knot) have Deering knotters, which make a standard knot.

Strength vs Performance

The ‘tensile’ strength of twine, is the strength in Kilogram Force (Kgf) at which a single, un-knotted, length of twine will break.

Once a knot is made in the twine, the overall ‘strength’ of the piece of twine is reduced, depending upon the type of knot that is made.

Because the Cormick and Deering knots are different, the overall twine ‘strength’ at the knot is different.

Cormick knot retains 75% of the twine’s original tensile strength

Deering knot retains only 55% of the twine’s original tensile strength

Twine with ‘tensile’ strength of 350 Kgf

- overall strength at the knot when made using a Cormick knot = 245 Kgf

- overall strength at the knot when made using a Deering knot = 192 Kgf

The same twine is 22% ‘weaker’ at the knot on the Deering knotter.

Comparing twine quality using the reference value of ‘knot strength’ of the twine is not accurate.

Without knowing which type of baler the twine will be used on (so knowing the retained strength of the twine after knotting), it is wrong to use ‘knot strength’ as a reference of security of the twine to hold the bale.

Most twine failures on a bale are a result of the knot opening after the bale is ejected from the baler, and NOT as a result of the twine breaking.

This is because many ‘old technology’ twine producers make twine heavier per metre, so making it thicker. Thicker twine is less able to make a stable knot, tightly formed with long tails, which increases the risk of the knot opening after the bale is released by the baler.