FARM GROWN SOLUTIONS

Anywhere that the net is in contact with metal, check for rough edges with a nylon stocking!

If the stocking snags, then it’s a good bet that the net will too. So, use the scotch-brite pad to rub it smooth.

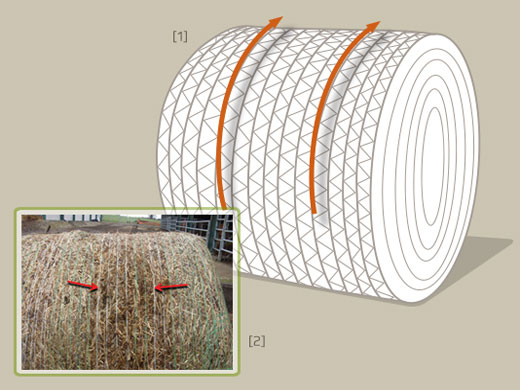

The only purpose of the lighter ‘shuss’ (zig-zag) threads is to hold the heavier ‘franze’ threads in place.[1]

This can easily be demonstrated by carefully cutting the zif-zag ‘shuss’ threads in the net around a bale, the bale will remain intact, showing clearly that ONLY the heavier threads are holding the bale. [2]

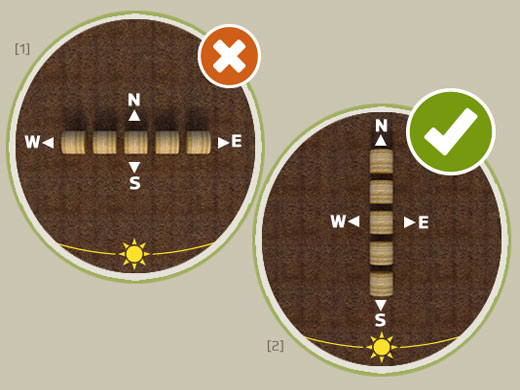

When storing hay and straw bales outside, it is important to store them in a way that BOTH sides of the bale obtain maximum sunshine, to help dry them out after rain.

The north facing side of bales stacked in an East –West alignment will NEVER be in the sunshine, so preventing a wet bale from drying out. [1]

Bales that are stacked in a North –South alignment will allow both sides of the bale to enjoy the drying properties of the sunshine. [2]

Anywhere the netwrap is in direct contact with metal surfaces should be clean and free from dirt or rust.

Never start the season like this….. clean it and remove all rust.

Stones or broken tines that get picked up by the baler will damage the surface of the rollers inside…..and cause the net to snag and tear, or pulling it off the bale surface and wrap on the rollers.

Inspect each roller carefully before you begin baling, it will be worth it in the end.

If the net feeds by powered feeding rollers, they must be adjusted correctly to give a uniform ‘pull’ on the net when feeding.

If you use a baler where the netwrap braking system works against the core…it is VERY IMPORTANT the core remains DRY!

In a New Holland, Krone or Welger type baler, net tension is created by holding the roll against the braking action, using teeth on the shaft that goes through the roll.

If the core is wet, the teeth cannot grip the inner core, so not achieving the tension needed.

New bales, at the start of the season can be damaged if bale holds-up in the chamber when it should be ejected. The rollers damage the net.

Rusty or paint on new baler sides will slow the bale from turning for the first number of bales.

Solution ….. Dis-engage PTO before ejecting the bale, until side walls are shined up.

stop putting the net ‘inside’ the bale!

The netwrap should always be on the OUTSIDE of the bale, otherwise it cannot hold the crop fully…

…the bale will enlarge and probably fall apart either by the outer layer being damaged or the lack of layers on the outside not being enough to contain the entire bale.

Solution: USE THE BRAKES !

Stop moving before the netwrap begins to feed, otherwise the bale continues being formed and the net ends up embedded inside the crop.

don’t let the net go over the edge!

Netwrap is designed so that ALL of the threads are present on the curved part of the bale surface and NOT over the sides (with the exception of the one special type of net designed to do this)

If any of the threads have spread too wide and are over the side of the bale, they are not giving any holding support for the crop.

If a net has 50 threads, and 3 are over each side (6 ‘lost’ from 50), this means the net has ‘lost’ 12% of its ‘holding force’.