FARM GROWN SOLUTIONS

Wrapping silage bales in plastic film offers great flexibility in operation, storage and feed quality. It also enables any excess to be transported conveniently, unlike clamp silage.

With effluent control legislation introduced in the mid 90’s, many farmers switched to silage bales as a means to store their valuable winter forage, as an alternative to expensive improvements required to older clamps.

When looking for a good silage wrap, the following points must be taken into consideration:

The main points include:

CO-EXTRUDED FILM

Mechanical Properties to ensure trouble-free operation in many vital stages of film application and bale handling.

The highest performance can be best achieved from a co-extruded film, allowing the various properties of the film’s ingredients to operate at their most efficient.

TEAR RESISTANCE

The film must have good tear resistance – to reduce breakages at the start of the bale wrapping cycle.

CLING

The film must have a good cling to provide an airtight seal when wrapping. This is essential to ensure all layers bond together and give the protection

needed to produce and maintain the valuable forage crop. A ‘sticky’ feeling film does not always mean the long-term tack level is good; likewise, if a film is noisy,

it does not necessarily suggest a better cling. Films which are very ‘sticky’ to touch are at risk from leaving tack deposits on pre-stretch rollers, leading to later problems.

PUNCTURE RESISTANCE

The film must have a high puncture resistance to withstand the forces of ejection from the turntable onto sharp crop stubble, as well as bale handling and stacking afterwards.

OPACITY

A consistent and uniform Opacity is essential for high quality silage production. When the film is stretched, the film colour must disperse evenly,

without visible ‘windows’ being produced in the film. Such problems could indicate not only a reduced film colour but also a reduction in the vital elements of UV protection

and cling where the film has ‘windowed’. If your film gives a very consistent Black dispersion, with no signs of windowing, it has good opacity.

U.V.

A high and consistent UV Stabilizer in the film is essential, as harmful ultra-violet radiation from the sun will degrade the quality of the film, eventually causing plastic to ‘break down’.

QUALITY I/D

Roll Identification and Quality Assurance. All good film manufacturers identify each roll with a unique i/d number, to provide absolute product traceability after production.

Such production standards not only offer product identification but also a guarantee of quality control and assurance that all products will be to the manufacturer’s consistent standard.

In order to ensure good, high quality silage bales certain important requirements must be met:

UNIFORM AND WELL SHAPED BALES

Important to ensure correct and efficient wrapping. This is of particular importance when wrapping net wrapped bales, as poor bale coverage by the net, resulting in ‘shoulders’ on the bale, will allow air to become trapped within the area between the ’shoulders’ – leading to spoilage and crop loss.

HIGH DRY MATTER BALES

Higher Dry Matter (DM) bales ensure good crop fermentation and also help wrapped bales maintain their shape after compression, aiding bale storage.

WRAP WITHIN 2 HOURS OF BALING

Extended wilt times will encourage the formation of fungi and will also reduce the nutrients in the crop.

WRAP CORRECTLY

Always ensure correct film application, ideally a MINIMUM of 6 layers (essential on Haylage crop), with a MINIMUM 50% overlap. To guarantee correct film application and overlap, film stretch must be controlled to the correct maximum of 70%, as an increase in film stretch causes excessive film ‘neck-down’ leading to reduced film overlap. This can be avoided by always maintaining the pre-stretch rollers clean and free from tack build-up, and maintaining correct turntable speeds, particularly when wrapping in higher ambient temperatures.

SIZE AND MISSHAPEN BALES

Remember – where a bale diameter exceeds 1.2m, the wrapper cannot provide a minimum 50% overlap without increasing the number of revolutions of the bale. This will also apply when wrapping mis-shapen bales.

STORE BALES CORRECTLY

- Very often the prime cause of crop spoilage is poorly stored bales.

- Wrapped bales should be stacked on their ends, allowing the maximum layers of film to be in contact with the ground for added

protection and eliminating the possibility of bales becoming mis–shaped by further stacking on top. - Low DM bales should never be stacked more than one layer high. This will avoid the seal on the film overlap opening through the

constant heavy pressure exerted on them from bales on top. - Always store wrapped bales away from trees, to avoid bird damage. Never leave wrapped bales out in the field for extended periods

after wrapping, as this too could encourage bird damage. - Always cover the completed bale stack with Novatex Silage Net, a close-weave raffia type net on a roll, with the net suspended

off the bales’ surface by old tyres (or similar) and weighted down at the floor.

Silage crop losses will occur if poor or incorrect procedures are used. The following guidelines

may help to pinpoint any potential problems:

POOR QUALITY CROP

- Crop not of optimum quality for cutting.

- Grass contaminated by soil due to mower setting too low.

- Extended wilting period allowing quality of crop to deteriorate.

- Poorly shaped bales, with ‘shoulders’, allowing air to become trapped during wrapping.

The use of a net, which can guarantee full width bale coverage, will avoid this.

FILM LAYERS OPENING

- Low cling properties of the film used.

- Insufficient layers of film applied.

- Crop, netwrap or twine protruding between layers preventing a good seal.

- Uneven film overlap on bale. This can be caused by:

- Incorrectly calibrated wrapper.

- Insufficient number of turns of the bale (minimum 16 turns for 750mm – 24 turns for 500mm – on a 1.2 x 1.2m bale, for 4-layer coverage.

For 6 layer coverage – turn bale 24 turns on 750mm filmand 36 turns for 500mm film.) - Oversized, or misshapen bales (where the greater circumference of the bale will require extra turns to ensure the correct overlap of film).

- Film over-stretches – often caused by over-tacked pre-stretch rollers.

FILM SPLITTING

Damaged film used during wrapping, causing it to tear when stretched

- Insufficient film applied

Most often found in the area of the bale ahead of the last film applied, signifying the need for another turn of the bale during wrapping.

Also, remember the first half turn of the bale is required to bring the film up to its full width on application to the bale. - Film Over-Stretch

Often caused by poorer quality film in higher ambient temperatures, excessive turntable speeds when wrapping or over-tacked

pre-stretch rollers causing an increase in film ‘neck-down’, leading to reduced film over-lap. - Bird damage

Usually very easy to identify, holes through all layers with crop pulled up through the film. Mostly, these holes are found on bale tops only,

though can occur at ground level when bales are left in the field after wrapping. This can be avoided by using Novatex Silage Nets, raffia style netting on a roll. - Punctured film

Often caused by wrapping crop with very high dry matter (DM), or when bales are ejected from turntable directly onto dry grass stubble.

For best results, always wrap in the same area of the field, to allow all bales to fall onto same smooth area on the floor.

FILM BREAKS WHEN WRAPPING

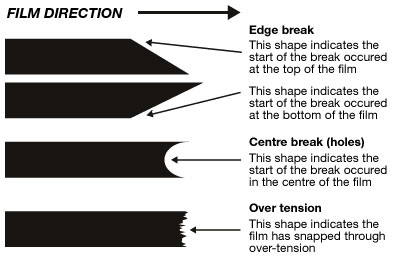

If film breaks when wrapping, a close examination of the film break profile will help to identify where the break began. From this, the cause of the break can often be traced back to either the roll, the bale or the film catching on the wrapper, depending where the break began.

The diagram below ilustrates this:

Guide to Stretchwrap usage based upon 4’ Round Bale Silage / Haylage

| Film Specification | Approx. No. Bales Per Roll (4’ Bale) | |

| 6 Layers | 4 Layers | |

| 500mm Wide x 1800m Long | 17 | 26 |

| 750mm Wide x 1500m Long | 22 | 33 |

Guide to Stretchwrap usage based upon Mini Bales Silage / Haylage

| File Specification | Approx. No. Bales Per Roll (Mini Bale) | |

| 6 Layers | 4 Layers | |

| 1800m Long x 250mm Wide | 17 | 26 |

How to calculate film usage

The number of bales that can be wrapped from a single roll of stretchfilm can be accurately calculated,

provided the following points are adhered to:

- THE BALES ARE 1.2m X 1.2m AND OF UNIFORM SHAPE.

- THE WRAPPER IS CALIBRATED FOR THE CORRECT NUMBER OF TURNS.

4 film layers 24 turns (500mm) or 16 turns (750mm)

6 film layers 36 turns (500mm) or 24 turns (750mm)

- THE FILM IS ACCURATELY AND CORRECTLY STRETCHED TO 70%.

If all the parameters are correct (bale size, film stretch of 70% and correct number of bale revolutions),

then the following figures will always be achieved.

Any variation to the above parameters will cause numbers to differ.

Given a standard bale size of 1.2m x 1.2m, applying film at 70% stretch using the correct number of turns for

the film width used (24 turns for 500mm and 16 turns for 750mm for 4 layers of film), the calculations are as follows:

A – BALE CIRCUMFERENCE (sum length of all four sides of the bale).

B – TURNS OF THE BALE.

C – FILM LENGTH AFTER STRETCH (film roll length plus 70%).

Multiply A x B and divide into C

| Film Width | A | B | C | Bales Per Roll |

| 500 mm | 4.8m (1.2m x 4 sides) |

24 | 3,060m (1,800m + 70%) |

26.5 |

| 750 mm | 4.8m (1.2m x 4 sides) |

16 | 2,550m (1,500m +70%) |

33.2 |