Netwrap Manufacturing

Netwrap is manufactured from High Density Polyethylene (HDPE), a thermoplastic resin produced from the chemical molecule ethylene. It is the most common polymer used in industry as it offers excellent properties of strength verses weight.

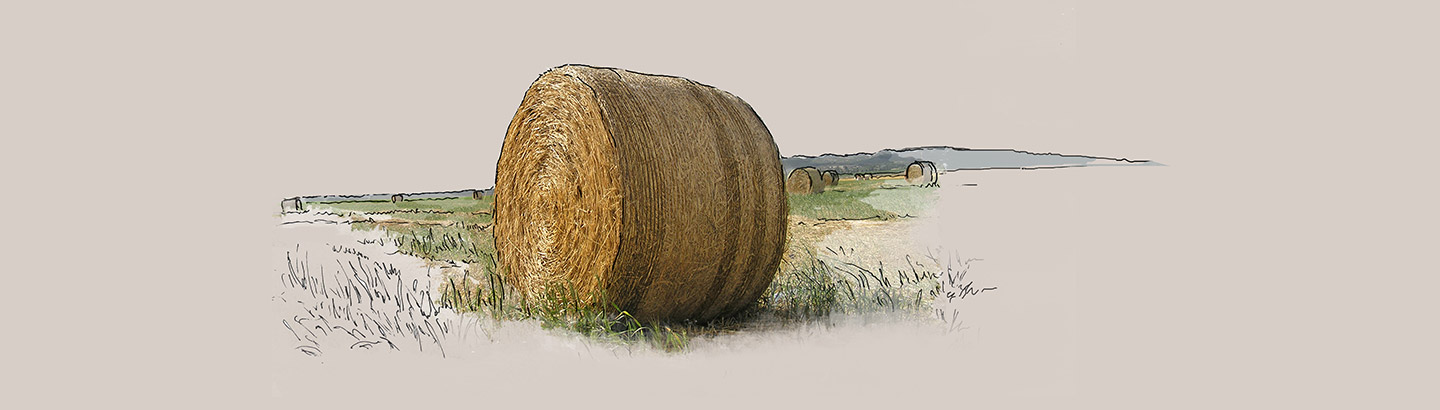

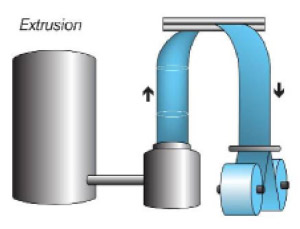

HDPE is the result of a process called polymerization, sometimes referred to as ‘cracking’, which combines small molecules (each called a ‘Mer’), into very large molecules (‘Poly-mers’). When the polymer resin is extruded for the manufacturing of netwrap, the molecules become arranged along the direction of the strand – ‘Machine Direction’ (or MD), giving the plastic a very high strength in this direction. When considered in this way, it is easy to see how such light material is able to withhold the extreme force of a dense and heavy round bale applied to the net, around the bale’s circumference – in the Machine Direction (MD) of the material used to construct the net.

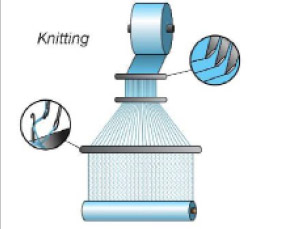

Traditional netwrap manufacturing involves a two-stage process. Firstly, the film is extruded into a wide plastic film and wound onto large sized ‘mother rolls’. The film from these rolls is then slit into narrow tapes, which are then knitted together on knitting looms to produce a net mesh.

|

|

Weight vs Strength

Normally, to increase the strength of plastic agricultural packaging (netwrap or baler twine for example) requires the use of heavier, or thicker, material. However, increasing the thickness and weight of the material, to achieve increased strength, will produce a heavier finished product; in the case of netwrap, a heavier material (increasing the grammes/metre of the netwrap) will result in a much heavier roll, with greater diameter, for the same roll length.

If a longer length roll is required, it is then impossible to maintain either a useful roll diameter to fit in the baler, or a suitable roll weight, when manufacturing with the heavier material.

It is not possible, when making netwrap with ‘standard’ raw material, to make a product with both higher strength and longer length, without the roll becoming too heavy or too big in diameter.

As an example:

| Netwrap strength |

g/m | Roll length |

Core weight |

Total Roll Weight (g/m x length + core) |

| 240kgf | 12 | 2,000m | 2kg | 26kg |

| 240kgf | 12 | 3,000m | 2kg | 38kg |

| 260kgf | 14 | 2,000m | 2kg | 30kg |

| 260kgf | 14 | 3,000m | 2kg | 44kg |

Raw Material Resins

Various netwrap manufacturers use different types of HDPE materials in the production process of bale nets. Higher grade, or better quality, resins will be able to produce higher strength polymers, likewise, a poorer grade of resin will not be as strong, for the same given weight of raw material.

Some netwrap manufacturing companies remain less sophisticated and unable to develop their product, or are less aware of how to develop, meaning they are forced to rely upon out-dated production methods. Consequently, these manufacturers have to depend upon ‘standard’, and therefore, ‘heavier’ materials to ensure a certain minimum strength and quality for their products.

Some netwrap manufacturing companies remain less sophisticated and unable to develop their product, or are less aware of how to develop, meaning they are forced to rely upon out-dated production methods. Consequently, these manufacturers have to depend upon ‘standard’, and therefore, ‘heavier’ materials to ensure a certain minimum strength and quality for their products.

Tama Group have developed a revolutionary advance in netwrap manufacturing, called Tama Light-Technology (LT), which combines an advanced formula of HDPE resin with a completely new production technology. Tama Light Technology has enabled the production of lighter-weight netwrap, which actually has strength greater than the ‘standard’ type of netwrap. This is a result of obtaining a higher ‘Relative Strength’ of raw material and is achieved by a unique step in the netwrap production process.

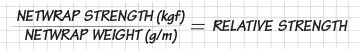

Relative Strength is the manufacturer’s scale of reference in achieving the highest strength (kgf) per gramme (g) of raw material.

RELATIVE STRENGTH

| Raw Material | Material Weight | Netwrap Strength | Relative Strength (Netwrap strength ÷ g/m) |

| Standard | 12 g/m | 240 kgf | 20 |

| Tama Light-Technology | 9 g/m | 250 kgf | 28 |

It is now very easy to see that it is NOT CORRECT to use the weight of the plastic (grammes per metre or g/m) as an indicator of the strength of the product.

| Raw Material | Netwrap Strength | g/m | Roll length | Total Roll Weight (g/m * length * core) |

| Standard | 240 kgf | 12 g/m | 2,000m | 26 kg |

| Standard | 240 kgf | 12 g/m | 3,000m | 38 kg |

| Tama Light-Technology | 250 kgf | 9 g/m | 3,000m | 29 kg |

Using Tama Light-Technology (LT) to increase strength, also allows the manufacturer to increase the roll length, without exceeding a useful roll weight and still within the tolerance of the roll diameter needed to fit in the baler.

Tama Light-Technology netwrap is 10 kgf STRONGER and not as heavy as ‘standard’ netwrap.

Environment

Tama Light-Technology plastic also has a strong Environmental benefit in agricultural use. Tama Light-Technology brings a lighter weight material, considerably less plastic is used to produce the same length of netwrap, compared with ‘standard’ netwrap production. Also, because Tama Light-Technology plastic is stronger than the ‘standard’ netwrap raw material, it can withhold the forces of the bale better.

Tama Light-Technology plastic also has a strong Environmental benefit in agricultural use. Tama Light-Technology brings a lighter weight material, considerably less plastic is used to produce the same length of netwrap, compared with ‘standard’ netwrap production. Also, because Tama Light-Technology plastic is stronger than the ‘standard’ netwrap raw material, it can withhold the forces of the bale better.

All Tama Netwrap products comply with the highest global standards and is also awarded Polagra Gold Medal.